Jul 01,2022

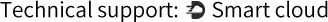

To ensure precision and reproducibility in measurements, a Fluorescence Immunoassay Analyzer typically integrates a combination of advanced technologies, quality control measures, and systematic procedures.

1. Automated Sample Handling and Process Control

-

Consistency in Sample Injection and Timing: One of the key factors influencing precision is the automation of sample handling. A Fluorescence Immunoassay Analyzer often incorporates automated liquid handling systems, which precisely manage the volume and timing of sample injections. This reduces the risk of human error or inconsistent sampling that could lead to measurement variability.

-

Automation of Reagent Addition: The analyzer also automates the addition of reagents to the samples. This ensures that the reagents are consistently added in the correct amounts and at the correct times, which is crucial for reproducibility, especially in fluorescence-based assays where even small variations in reagent concentration can lead to significant differences in results.

2. Regular Calibration and Use of Standards

-

Establishing Calibration Curves: Calibration is central to achieving consistent and reliable results over time. The analyzer is calibrated with known standards—either in-house or commercially available—to establish a baseline response. The system then uses these calibration curves to interpret fluorescence signals accurately for unknown samples.

-

Recalibration for Consistency: Over time, instruments can experience slight shifts in their response characteristics due to component wear or environmental changes. Regular recalibration, typically performed after a set number of tests or at specific intervals, helps maintain accuracy. This recalibration ensures that any fluctuations or drifts in the system are accounted for, ensuring long-term reproducibility.

3. Stable Light Source and Optical System

-

High-Quality Light Sources: The stability of the fluorescence excitation source is critical. A high-quality Fluorescence Immunoassay Analyzer uses a stable and reliable light source—usually a laser or an LED—that minimizes fluctuations in intensity. Any variation in the light source can lead to inconsistencies in the emission signals detected, which would, in turn, affect the precision of the results. A stable light source is necessary to produce a consistent fluorescence signal.

-

Optical Path Alignment: The optical system within the analyzer, including light filters, mirrors, and detectors, needs to remain precisely aligned. Even slight misalignments can lead to inaccurate readings. Some analyzers incorporate self-aligning systems or automatic calibration of the optical components, ensuring they stay in optimal condition for each measurement.

4. Environmental Control Systems

-

Temperature and Humidity Regulation: Environmental conditions, such as temperature and humidity, can significantly impact the performance of a fluorescence analyzer. Many advanced systems include built-in temperature control to stabilize the environment within the sample chamber. This minimizes the risk of environmental variations influencing the assay results, contributing to improved reproducibility across testing conditions.

-

Humidity Control: In some cases, analyzers also feature systems to regulate humidity levels, as changes in moisture can alter the fluorescence characteristics of certain reagents or analytes.

5. Data Normalization and Signal Correction Algorithms

-

Background Noise Removal: Fluorescence measurements can be affected by background fluorescence, or ‘noise,’ which may originate from impurities in the sample or surrounding materials. High-quality systems incorporate algorithms to subtract or normalize this background noise from the final signal, ensuring that the fluorescence measurement is only influenced by the analyte of interest. This enhances the precision of the result.

-

Compensation for Sample Variability: Automatic data correction algorithms also help to compensate for any inherent variability in the samples, such as differences in sample volume, path length, or slight fluctuations in reagent behavior. This ensures that measurements are comparable and consistent across different runs and sample types.

6. Reagent and Consumable Quality Control

-

Consistent Reagents and Buffers: The use of high-quality reagents that are consistent in terms of purity and performance is vital to reproducibility. Even small deviations in reagent quality can lead to variability in results. Some analyzers come with internal checks or automatic alerts when reagents are nearing expiration or are showing signs of degradation, ensuring that only high-quality reagents are used.

-

Validation of Reagents: Certain systems also validate reagents before they are used in assays, ensuring that they meet the necessary performance criteria, such as the correct fluorescence emission spectra, sensitivity, and stability.

7. Internal Quality Control (IQC) and Run Verification

-

Built-in Quality Checks: Many analyzers incorporate an internal quality control system that performs regular checks on the instrument’s performance during each analysis. This might involve running known control samples or checking for system errors that could compromise accuracy. This ensures that any potential issues are detected early, and the analysis is either corrected or halted before unreliable data is generated.

-

Run Verification: The system often verifies that each run meets predefined criteria for accuracy before proceeding with final results. This adds another layer of assurance that the data obtained is reliable and reproducible.

8. Replicate Measurements and Statistical Control

-

Multiple Replicates for Increased Precision: To ensure that any observed result is not due to random error, many systems process multiple replicates of each sample. Replicates reduce the effect of outliers and minimize the chances of errors from individual measurements. Statistical analysis of the replicates can provide a more accurate representation of the true analyte concentration.

-

Statistical Control of Data: Some analyzers incorporate built-in statistical tools that monitor the variation in results over time. If the variance exceeds predefined limits, the system may alert the operator or automatically correct for potential issues.

9. Routine Maintenance and Calibration Schedules

-

Scheduled Maintenance: Routine maintenance, such as cleaning optical components and checking calibration standards, ensures that the analyzer remains in optimal working condition. Regular maintenance is crucial for sustaining long-term precision and ensuring that all system components (such as detectors, light sources, and filters) function as expected.

-

Component Lifespan Management: Key components like light sources and detectors typically have a defined lifespan. The analyzer may include alerts when these components need replacing, ensuring that there is no degradation in performance over time. Early detection of issues helps prevent inaccurate measurements due to component failure.

10. User Training and Standard Operating Procedures (SOPs)

-

Standardization of Processes: Even with the most advanced technology, human factors can still affect precision and reproducibility. To minimize this, analyzers are often used in conjunction with detailed Standard Operating Procedures (SOPs). These procedures standardize the way samples are prepared, how reagents are handled, and how the analyzer is operated. Proper user training ensures that the analyzer is used in the most effective way, reducing the likelihood of operational errors that could compromise measurement accuracy.

Español

Español

Français

Français

Deutsch

Deutsch

عربى

عربى